The first thing taught in Operations Management classes is how to avoid the points of congestion commonly called bottlenecks. These elements absolutely need to be solved as they have a major role in determining the throughput of the whole supply chain. To illustrate it, picture a workflow built to accomplish many tasks (no automation): preflighting, color management, batching, imposition, managing print, and perhaps finishing or binding. Now, imagine that the imposition requires many checks by the operator. When a significant flow of jobs comes in from upstream store-front or FTP, all steps work but then, start cumulating and create a bottleneck at the imposition due to manual checking of various adjustments. Perhaps this bottleneck increases further at the bindery due to another manual checking because of job variables. This is when you raise a red flag.

How to avoid these points of congestion? How to increase throughput in this production chain?

Eliminate Bottlenecks with Automation

The printing industry has undeniably transformed over the past years. The new print manufacturing workflow must be made more flexible, thus reshaping the way print service providers implement prepress work in relation to their manufacturing processes. The increased volume of short-runs and personalized orders pushed many traditional offset printers to invest in digital presses. Although these presses bring major advantages, they need to be fed with print-ready PDFs at the same rate as they print in order to exploit their full potential. There is no longer room for bottlenecks.

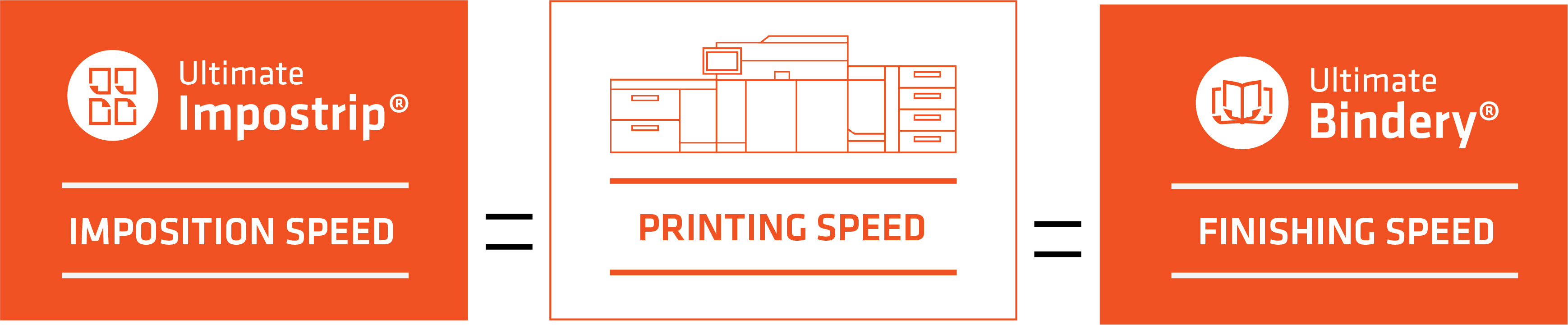

The prepress department has also been affected by the ‘’Digital Revolution’’. Indeed, it takes more time to impose 50 orders of 100 pages than one order of 5000 pages. Manual imposition in Adobe InDesign or other similar programs does not work anymore. Printers who insist to do prepress the way they used to now realize that prepress is the starting point that affects their whole workflow. Like a hiker who sets the pace in leading its group on a trail, prepress is leading the print production and sets the pace for printing and finishing. Imposition, printing and finishing speed must be the same, and with digital presses printing 100 m/minute, it is only achievable with upstream and downstream automation. This means automation in pre and post press.

Imposition Automation with Ultimate Impostrip®

Well-known in the industry, Ultimate Impostrip® is the first digital imposition solution in the market launched in 1989. Designed with productivity in mind, it optimizes every aspect of the prepress imposition workflow with tools that are easy-to-use yet extremely versatile.

Our imposition software proposes adapted ways to deliver the flexibility and versatility needed for a profitable production environment requiring automatic numbering logics built off device preferences and variable impressions for best optimization. Providers can streamline multiple size gang runs independently of the respective content and size as it no longer needs to batch similar jobs together when taking advantage of dynamic variable frame size logic. Our customers can put complex finishing lines in place knowing all their imposition requirements are already built into Ultimate Impostrip® engine.

Connectivity is key to achieve a high-speed printing environment. Ultimate Impostrip® can be easily integrated into any prepress workflow.

Easy. The user Web2Print software simply sends a job ticket to Ultimate Impostrip® which will automatically read it, generate the imposition and send the imposed file to any RIP.

Simple. The job ticket automatically triggers the imposition. Ultimate Impostrip® remembers the structure of the upstream ticketing system. Every time a customer sends an order, it will automatically be imposed by Ultimate Impostrip® with the proper quantity and specifications using Hot Folder Automation.

Intelligent. With the new Imposition Agent, introduced with Ultimate Impostrip® 2019, the user only needs to setup one Hot Folder by product (ex: business cards). Ultimate Impostrip® will then analyze all the templates for that product and select the best optimal layout to maximize the coverage on the sheet. This AI-driven feature tremendously helps to generate the best imposition possible. It’s like having an intelligent virtual employee at your service.

The user can configure the Hot Folder with dynamic marks and barcodes using Marks Profile. Ultimate Impostrip® will automatically retrieve the content information from the XML ticket, create the marks and barcodes with the embedded content information and place them at the exact position related to the gutter, page or sheet as specified in the Marks Profile. Very useful to track the orders on the production floor, barcodes and marks can be also used for finishing.

Finishing Automation using Ultimate Bindery®

Ultimate Bindery® is a standalone solution designed to fill the gap between prepress and finishing. It is a JDF automation solution out-of-the-box. No programming needed. Ultimate Bindery® software reshapes the industry at a time where commercial and book printers are facing challenges in the bindery department over short runs. We undertake this challenge and propose a solution to the traditional bindery work to address the paradigm of variable length and size publications and multi-component binding projects on any type of finishing systems. Ultimate Bindery® pioneer contribution is to resolve this challenge with much simplicity and high level of intra-machine operability and connectivity.

Ultimate Bindery® takes the JDF imposed job generated by Ultimate Impostrip® and complete it with all the necessary parameters needed to automatically set up the finishing equipment such as perfect binder, saddle-stitcher, cutter, slitter-creaser, 3-knife cutter, etc. The user doesn’t need to manually set-up every job and every finishing equipment anymore which is a major time and resources saver. Imagine: As soon as a job is printed, it is finished and ready to be shipped. No stacks of paper laying around on the grounds, waiting to be finished. Ultimate Bindery® sends the parameters to finish each of the printed jobs, one after another so both printing and finishing equipment work at their fullest capacities.

Ultimate Bindery® is a hub of knowledge of over 20 different finishing devices from different manufacturers. It operates as a central location to validate that each job is built respecting the capabilities and constraints of the selected finishing equipment, before even printing it. These validations prevent errors and reduce waste since an alert is sent to the user for them to rectify the situation. It eliminates the need for trial runs thus reducing printed paper waste thanks to the preflighting capability of its engine.

End-to-End Workflow Automation

Ultimate Impostrip® and Ultimate Bindery® are the Ultimate software solutions that integrates seamlessly with Enfocus Switch. With our Switch configurator, our professional imposition and digital finishing automation solutions are the unique grinds each digital printing production can add to get the perfect terroir for efficient and profitable operation. The benefits are abundant.

MORE:

+ Jobs out of the door every day;

+ Money in business accounts;

+ Customer satisfaction for respecting the delivery delays;

+ Repeated business due to a reliable and trustable service;

LESS:

– Overtime;

– Specialized employees;

– Re-runs of jobs;

– Waste of paper and ink;

Imposition + Finishing Automation = The recipe to grow a business. By opting for Ultimate Impostrip® and Ultimate Bindery®, the user becomes competitive in his market, automatically!

[This article was published in The Enfocus Workflow Automation Report in October 2019]